pengenalan

Penggunaan cerucuk paip dalam pembinaan asas telah menjadi pilihan popular selama bertahun-tahun. Buasir paip digunakan untuk memindahkan beban struktur ke lebih dalam, lapisan tanah atau batu yang lebih stabil. Namun begitu, dalam keadaan tanah lembut, Kaedah longgokan paip tradisional mungkin tidak sesuai kerana risiko gosok atau ubah bentuk. Dalam kertas kerja ini, Kami akan meneroka pelbagai kaedah longgokan paip yang tersedia yang sesuai untuk keadaan tanah lembut.

KAPASITI LONGGOKAN

2.1 Kapasiti paksi

Sebelum membincangkan ujian beban longgokan sebenar yang dilakukan dan keputusan dan kesimpulan daripada mereka

Ujian, Kajian ringkas mengenai kapasiti longgokan secara amnya disediakan. Secara amnya, seperti yang dinyatakan sebelum ini, a

Longgokan di dalam tanah adalah berkesan sebagai penyelesaian asas yang mendalam kerana ia paling sering memindahkan beberapa

beban yang digunakan secara paksi ke tanah yang biasanya lebih dalam dan mengurangkan penyelesaian. Pemindahan beban ini adalah

fenomena yang berlaku kerana interaksi tanah dan longgokan dan tanah berhampiran pangkalan

daripada longgokan. Dalam erti kata lain, kapasiti paksi muktamad, Qu, bahawa longgokan boleh ada adalah penjumlahan

geseran kulit yang dibangunkan di antara sisi longgokan dan tanah, S, dan galas

kapasiti tanah di hujung longgokan, Qp (Das, 2004) sedemikian rupa sehingga

Qu Qp Qs ........................(Eq. 2.1)

Ini ditunjukkan dalam Rajah 2.1 untuk longgokan yang didorong ke dalam tanah jarak, L, dari permukaan dan

Menyimpulkan kuasa paksi.

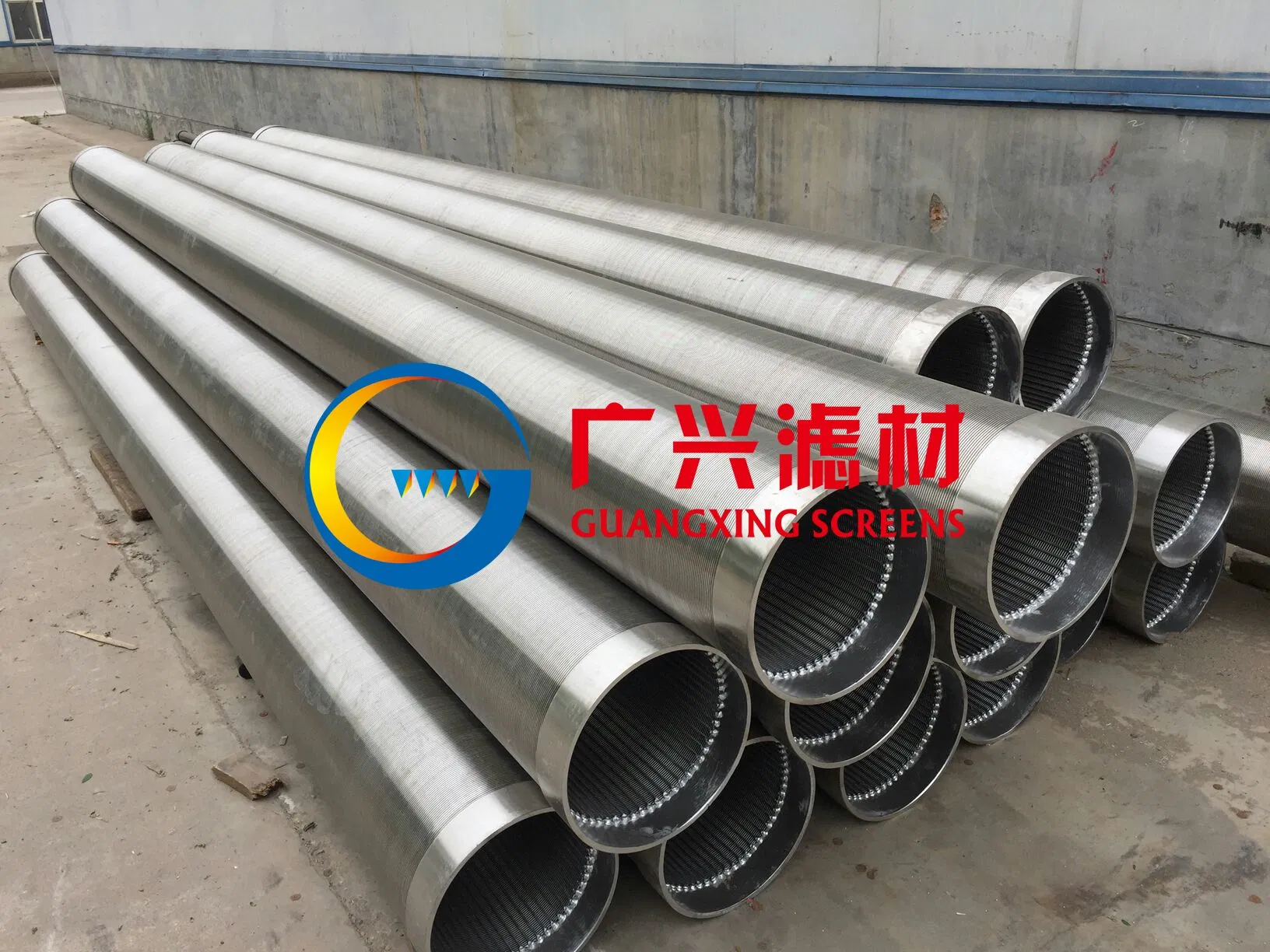

Penerangan Produk

| Nama Produk | Paip / Tiub Keluli dikimpal | Teknik | Dikimpal |

| Panjang | 5.8m-12m atau sebagai permintaan anda | Toleransi | Ketebalan dinding:Panjang ±0.05MM:±Diameter Luar 6mm:±0.3J |

| Ketebalan dinding | 1mm-12mm atau sebagai permintaan anda | Diameter luar | 20mm-508mm atau sebagai permintaan anda |

| Standard | API 5L ASTM A53-2007 ASTM A671-2006 ASTM A252-1998 ASTM A450-1996 ASME B36.10M-2004 ASTM A523-1996 BS 1387 BS EN10296 BS 6323 BS 6363 BS EN10219 GB/T 3091-2001 GB/T 13793-1992 GB/T9711 |

Gred | SPCC SPCD SPCE ST12-15 DC01-06 Q195A-Q235A Q195AF-Q235AF Q295A(B)-S345A(B) |

| Paip Tamat | Serong/Dilindungi oleh topi plastik pada kedua-dua hujungnya / Potong quare / Grooved / Threaded dan Gandingan dll. | Permohonan | Digunakan secara meluas dalam perabot,hiasan dalaman, saluran paip cecair, Industri petroleum dan gas asli, Penggerudian, Paip, Struktur |

| Sijil | API/BIS/SABS/JIS/GS/ISO9001 | Masa Penghantaran | 15-21 Hari |

1 Skematik menunjukkan longgokan biasa yang didorong ke dalam tanah dan daya

Terlibat dalam menentukan kapasiti longgokan.

Sebaik sahaja longgokan didorong dan disediakan dan beban yang mesti ditolak oleh longgokan meningkat, kapasiti beban di sepanjang aci dan di hujung digerakkan. Bahagian beban yang dibawa oleh

aci berbeza-beza sepanjang panjang longgokan sehingga maksimum berhampiran permukaan tanah dan

Curvilinearly berkurangan ke bahagian beban yang dibawa oleh hujung longgokan. Lymon Reese dan beliau

rakan sekerja menangkap penjelasan yang diterima umum ini dalam Rajah 2.2 (Reese et. Al, 2006).

Rintangan geseran unit di sepanjang aci, f, sebaliknya, adalah nisbah kapasiti beban unit di sepanjang aci, ΔQs, kepada produk perimeter longgokan, p, dan unit

panjang sepanjang aci, ΔL, sedemikian rupa sehingga

p L

Q f s

................................................................(Eq. 2.2)

Geseran unit di sepanjang aci ini berbeza-beza sehingga sifar berhampiran permukaan tanah, bertambah

melengkung kepada beberapa nilai maksimum berhampiran 65% kedalaman cerucuk dari permukaan tanah

kemudian melengkung menurun kepada beberapa nilai lebih besar daripada sifar di hujung cerucuk seperti yang ditunjukkan dalam

Rajah 2.3.

Fenomena beban paksi yang digunakan dipindahkan ke tanah dan oleh itu kapasiti pembawa beban cerucuk sangat bergantung kepada kaedah pemasangan (Reese et. Al,

2006). Walaupun cerucuk boleh dipasang melalui membosankan dan bergetar, timbunan yang penyelidikan ini akan

tumpuan telah dipasang melalui teknik pemanduan biasa. Aspek lain yang boleh menjejaskan

proses pemindahan beban ialah bahan cerucuk digerakkan dan jenis cerucuk

diri mereka sendiri. Seterusnya, jenis tanah dan cara kapasiti cerucuk paksi dibangunkan

dalam setiap akan dijelaskan. Selepas itu, cerucuk sebenar yang digunakan di setiap tapak ujian beban cerucuk dan mereka

kapasiti teori akan dibincangkan.

Latar belakang

Cerucuk paip biasanya diperbuat daripada keluli atau konkrit dan terdapat dalam pelbagai bentuk dan saiz. Ia biasanya digunakan dalam pembinaan asas untuk menyokong struktur seperti bangunan, jambatan, dan platform luar pesisir. Cerucuk paip didorong ke dalam tanah menggunakan pemacu cerucuk, yang memaksa cerucuk masuk ke dalam tanah sehingga mencapai kedalaman yang telah ditetapkan. Setelah longgokan berada di tempatnya, ia menyediakan asas yang kukuh dan stabil untuk struktur yang dibina.

Dalam keadaan tanah lembut, Kaedah longgokan paip tradisional mungkin tidak sesuai kerana risiko gosok atau ubah bentuk. Keadaan tanah lembut dicirikan oleh kekuatan tanah yang rendah, kebolehmampatan yang tinggi, dan kandungan air yang tinggi. Keadaan ini boleh menyebabkan cerucuk berubah bentuk atau strap di bawah berat struktur yang sedang dibina, yang boleh menjejaskan kestabilan asas.

Kaedah Cerucuk Paip untuk Tanah Lembut

Terdapat beberapa kaedah cerucuk paip tersedia yang sesuai untuk keadaan tanah lembut. Kaedah-kaedah ini direka bentuk untuk meminimumkan risiko lengkokan cerucuk atau ubah bentuk dan menyediakan asas yang kukuh dan stabil untuk struktur yang dibina.

Cerucuk Paip Keluli dengan Plat Heliks

Cerucuk paip keluli dengan plat heliks adalah pilihan yang popular untuk keadaan tanah yang lembut. Cerucuk ini diperbuat daripada keluli dan mempunyai plat heliks yang dipasang pada aci cerucuk. Plat heliks bertindak sebagai sauh, memberikan sokongan dan kestabilan tambahan kepada cerucuk. Plat heliks biasanya dipasang pada selang waktu sepanjang aci cerucuk, dengan jarak antara plat ditentukan oleh keadaan tanah.

Proses pemasangan cerucuk paip keluli dengan plat heliks adalah serupa dengan cerucuk paip tradisional. Cerucuk didorong ke dalam tanah menggunakan pemacu cerucuk, dan plat heliks diskrukan ke dalam tanah apabila cerucuk didorong lebih dalam. Plat heliks memberikan sokongan dan kestabilan tambahan kepada cerucuk, mengurangkan risiko cerucuk lekuk atau ubah bentuk.

Cerucuk Paip Keluli dengan Lubang Pra-Bosan

Cerucuk paip keluli dengan lubang pra-bosan adalah pilihan lain untuk keadaan tanah yang lembut. Cerucuk ini diperbuat daripada keluli dan mempunyai lubang pra-bored di sepanjang aci cerucuk. Lubang pra-bored biasanya diisi dengan grout atau konkrit, memberikan sokongan dan kestabilan tambahan kepada cerucuk.

Proses pemasangan cerucuk paip keluli dengan lubang pra-bosan adalah serupa dengan cerucuk paip tradisional. Cerucuk didorong ke dalam tanah menggunakan pemacu cerucuk, dan lubang pra-bored diisi dengan grout atau konkrit kerana cerucuk didorong lebih dalam. Grout atau konkrit memberikan sokongan dan kestabilan tambahan kepada cerucuk, mengurangkan risiko cerucuk lekuk atau ubah bentuk.

Cerucuk Paip Keluli dengan Lengan Keluli

Cerucuk paip keluli dengan lengan keluli adalah pilihan lain untuk keadaan tanah yang lembut. Cerucuk ini diperbuat daripada keluli dan mempunyai lengan keluli yang dipasang pada batang cerucuk. Lengan keluli bertindak sebagai tetulang, memberikan sokongan dan kestabilan tambahan kepada cerucuk.

Proses pemasangan cerucuk paip keluli dengan lengan keluli adalah serupa dengan cerucuk paip tradisional. Cerucuk didorong ke dalam tanah menggunakan pemacu cerucuk, dan lengan keluli dilekatkan pada aci cerucuk apabila cerucuk didorong lebih dalam. Lengan keluli memberikan sokongan dan kestabilan tambahan kepada cerucuk, mengurangkan risiko cerucuk lekuk atau ubah bentuk.

Cerucuk Paip Keluli Berisi Konkrit

Cerucuk paip keluli berisi konkrit adalah pilihan lain untuk keadaan tanah yang lembut. Cerucuk ini diperbuat daripada keluli dan diisi dengan konkrit. Konkrit memberikan sokongan dan kestabilan tambahan kepada cerucuk, mengurangkan risiko cerucuk lekuk atau ubah bentuk.

Proses pemasangan cerucuk paip keluli berisi konkrit adalah serupa dengan cerucuk paip tradisional. Cerucuk didorong ke dalam tanah menggunakan pemacu cerucuk, dan cerucuk diisi dengan konkrit kerana cerucuk didorong lebih dalam. Konkrit memberikan sokongan dan kestabilan tambahan kepada cerucuk, mengurangkan risiko cerucuk lekuk atau ubah bentuk.

Kesimpulan

Kesimpulannya, terdapat beberapa kaedah cerucuk paip tersedia yang sesuai untuk keadaan tanah lembut. Kaedah-kaedah ini direka bentuk untuk meminimumkan risiko lengkokan cerucuk atau ubah bentuk dan menyediakan asas yang kukuh dan stabil untuk struktur yang dibina. Cerucuk paip keluli dengan plat heliks, cerucuk paip keluli dengan lubang pra-bosan, cerucuk paip keluli dengan lengan keluli, dan cerucuk paip keluli berisi konkrit adalah semua pilihan yang berdaya maju untuk keadaan tanah yang lembut. Pilihan kaedah akan bergantung kepada keadaan tanah tertentu dan keperluan struktur yang dibina. Adalah penting untuk berunding dengan jurutera yang berkelayakan untuk menentukan kaedah cerucuk paip yang paling sesuai untuk projek tertentu.