Сеточки для колодцев и гравийные набивки: Углубленный анализ особенностей, Приложения, и преимущества

Оглавление

- Введение на скважины и гравийные пакеты

- Ключевые функции скважины и гравийных пакетов

- Материалы, используемые на экранах скважины и гравий

- Размеры и параметры настройки

- Важность размера слота и сопоставления частиц

- Преимущества использования скважины и гравийных пакетов

- Типы вариантов гравия

- Применение скважины и гравийных пакетов

- Технические характеристики экранов скважин и гравийных пакетов

- Преимущества экранов скважин Abtersteel и гравийных пакетов

- Сравнение вариантов материала

- Эффективность установки и эксплуатации

- Техническое обслуживание и долговечность

- Рыночные тенденции и инновации

- Заключение

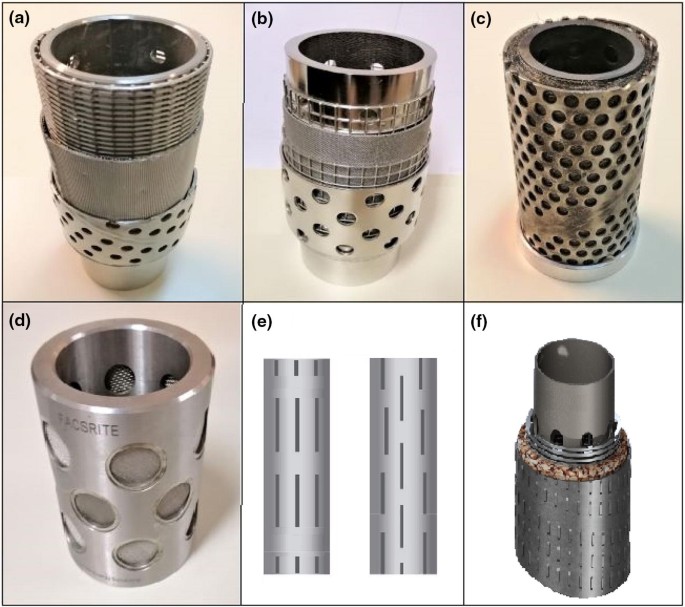

1. Введение на скважины и гравийные пакеты

Скважины экраны и гравийные пакеты являются незаменимыми компонентами в водяных скважинах и масле & извлечение газа. Эти продукты действуют как системы фильтрации, обеспечение эффективного контроль песка и облегчать непрерывные операции. Интеграция передовых материалов и точного проектирования повышает их эффективность, Сделать их краеугольным камнем в буровой индустрии.

2. Ключевые функции скважины и гравийных пакетов

Хорошо экраны и гравийные пакеты выделяются из -за их уникальных функций:

| Особенность | Преимущества |

|---|---|

| Максимальные открытые площадки | Повышает производительность жидкости при сохранении структурной целостности. |

| Точные размеры слотов | Облегчает работу без песка, Сокращение требований к техническому обслуживанию. |

| Минимальная скорость входа | Обеспечивает падения низкого давления, повышение эффективности системы. |

| Стабильная и надежная конструкция | Повышает безопасность эксплуатации с высокой прочностью и долговечностью. |

| Превосходная коррозионная стойкость | Минимизирует риски, связанные с износом окружающей среды. |

| Меньше засорения рисков | Способствует последовательной производительности за счет сокращения операционных сбоев. |

3. Материалы, используемые на экранах скважины и гравий

Материалы, используемые для этих продуктов, имеют решающее значение для определения их производительности и срока службы. Общие материалы включают в себя:

- Нержавеющая сталь 304/304L, 316/316л: Provides robust corrosion resistance, ideal for harsh environments.

- Monel or Required Alloys: Specialized alloys designed for unique operational needs, ensuring strength and flexibility.

Material Comparison Table:

| Материал | Устойчивость к коррозии | Сила | Приложения |

|---|---|---|---|

| SS 304/304L | Высокий | Умеренный | General-purpose applications. |

| SS 316/316L | Очень высокий | Высокий | Marine and saline environments. |

| Монель | Exceptional | Высокий | Acidic and harsh chemical environments. |

4. Размеры и параметры настройки

Well screens and gravel packs can be tailored to meet specific operational requirements:

| Параметр | Standard Range | Custom Options |

|---|---|---|

| Длина | 4.5–12 m | Customized as per client needs. |

| Размер слота | 0.1–3 мм | Precision-engineered to match particle sizes. |

| Наружный диаметр | 73–355 mm | Adjustable dimensions for varied uses. |

This flexibility ensures compatibility across diverse geological formations and operational conditions.

5. Важность размера слота и сопоставления частиц

The slot size of well screens and the particle size of gravel packs must align to achieve optimal performance. This precision matching ensures:

- Эффективная фильтрация: Блокирует нежелательные частицы, позволяя проход жидкости.

- Улучшенная система долголетия: Уменьшает износ, вызванный смещенными размерами частиц.

6. Преимущества использования скважины и гравийных пакетов

Интеграция экранов скважин и гравийных пакетов обеспечивает многочисленные преимущества:

- Повышенная производительность: Максимизируя открытые площадки, Скорость потока жидкости значительно увеличивается.

- Экономическая эффективность: Минимизированные сбои на техническое обслуживание и эксплуатацию приводят к снижению затрат.

- Защита окружающей среды: Снижает риски эрозии и загрязнения.

7. Типы вариантов гравия

Abtersteel предлагает широкий спектр вариантов гравия, чтобы дополнить свои скважины экраны:

| Тип гравия | Характеристики | Приложения |

|---|---|---|

| Гравийный песок | Высокая проницаемость, естественная фильтрация. | Общая вода хорошо использует. |

| Стеклянные бусинки | Единый размер, высокая прочность. | Системы точности фильтрации. |

| Кварц песок | Устойчивый к истиранию, прочный. | Суровые операционные среды. |

| Керамические проппаты | Легкий, Высокая устойчивость к раздавливам. | Добыча нефти и газа. |

8. Применение скважины и гравийных пакетов

Хорошо экраны и гравийные пакеты жизненно важны в различных отраслях промышленности:

- Водяные колодцы: Обеспечение чистоты, Бес песочного водоснабжения.

- Масло & Газовые скважины: Облегчение эффективного извлечения путем предотвращения блокировки.

- Геотермальная энергия: Оптимизация теплопередачи в геотермальных системах.

- Сельскохозяйственные скважины: Поддержка ирригационных систем с непрерывным потоком.

9. Технические характеристики экранов скважин и гравийных пакетов

| Спецификация | Подробности |

|---|---|

| Базовая труба | Перфорированная тарелка. |

| Внешний кожух | Клин -проволочный экран (Экран Джонсона). |

| Внутренний диаметр | 60–340 мм. |

| Связь | Сварное кольцо, STC/LTC/BTC Thread. |

Эти спецификации обслуживают высокопроизводительные требования, обеспечение долговечности и операционной эффективности.

10. Преимущества экранов скважин Abtersteel и гравийных пакетов

Продукты Abtersteel уникально позиционируются, чтобы предложить:

- Пользовательский дизайн: Адаптировано для удовлетворения точных потребностей каждого проекта.

- Широкий диапазон материалов: Нержавеющая сталь для специализированных сплавов.

- Глобальная совместимость: Приверженность международным стандартам.

11. Сравнение вариантов материала

| Материал | Расходы | Долговечность | Распространенное использование |

|---|---|---|---|

| Нержавеющая сталь | Умеренный | Высокий | Водяные и масляные скважины. |

| Монель | Высокий | Exceptional | Суровая химическая среда. |

| Композитные материалы | Варьируется | Высокий | Пользовательские решения. |

12. Эффективность установки и эксплуатации

Эффективная установка и эксплуатация являются ключевыми для максимизации преимуществ скважины и гравийных пакетов. Abtersteel предоставляет:

- Комплексные руководящие принципы: Чтобы упростить процесс установки.

- Поддержка после установки: Обеспечивает бесшовную интеграцию с существующими системами.

13. Техническое обслуживание и долговечность

Регулярное обслуживание скважинных экранов и гравийных пакетов может продлить их срок службы. Продукты Abtersteel разработаны для:

- Низкие потребности в техническом обслуживании: Устойчивый к засолу и коррозии.

- Высокая долговечность: Выдерживает экстремальные условия эксплуатации.

14. Рыночные тенденции и инновации

Последние достижения в отрасли включают:

- Улучшенная точность слота: Улучшение возможностей фильтрации.

- Устойчивые материалы: Акцент на экологически чистых материалах.

- Мониторинг с Двигателем ИИ: Обеспечение отслеживания производительности в реальном времени.

15. Заключение

Скважины и гравийные пакеты жизненно важны для эффективных и устойчивых операций в различных отраслях промышленности. Abtersteel выделяется своими инновационными дизайнами, Высококачественные материалы, и приверженность совершенству. Будь то водяные скважины или добыча нефти, Эти продукты обеспечивают оптимальную производительность, надежность, и долголетие.

Часто задаваемые вопросы

- Какие материалы обычно используются для скважины? Нержавеющая сталь (SS 304/304L, 316/316л) и Monel распространены из -за их силы и коррозионной стойкости.

- Как определяется размер слота на экранах скважины? Инженеры соответствуют размеру слота с размером частиц формирования для эффективной фильтрации.

- Каковы преимущества использования гравийных пакетов? Гравийные упаковки предотвращают вторжение песка, повысить производительность, и продлить срок службы колодца.

- Можно хорошо настраивать экраны и гравийные пакеты? Да, Abtersteel предлагает индивидуальные размеры и материалы в соответствии с конкретными потребностями проекта.

- Какие отрасли используют хорошо экраны и гравийные пакеты? Они используются в водных скважинах, масло & извлечение газа, геотермальная энергия, и сельского хозяйства.

- Что делает продукты Abtersteel уникальными? Их настраиваемые дизайны, Высококачественные материалы, и соблюдение глобальных стандартов выделяет их.