Straight Web Sheet Piles: Design and Applications

Introduction to Straight Web Sheet Piles

Straight web sheet piles are specialized steel sections designed to form cylindrical or diaphragm-shaped structures, typically used in civil engineering for retaining soil or water in challenging conditions. Unlike traditional sheet piles, which rely on bending strength and stiffness, straight web sheet piles function as gravity cells, held together by the tensile strength of their interlocks. These structures are particularly suited for projects where rock layers are near the surface, excavation depths are significant, or anchoring is impractical, such as in cofferdams, quay walls, and port constructions. The large diameter of the cells and the contained soil mass ensure stability through their own weight, making them ideal for both temporary and permanent applications.

The design of straight web sheet piles focuses on horizontal traction forces, requiring interlocks with high declutching resistance. These interlocks allow for rotation up to 4.5 degrees per interlock, with special bending enabling up to 12 degrees, providing flexibility in forming circular or diaphragm cells. Manufacturers like ArcelorMittal and Nippon Steel produce straight web sheet piles with robust interlock designs, adhering to standards like EN 10248 for geometric tolerances and EN 12063 for welded junctions. Their high tensile strength, often exceeding 5,500 kN/m, makes them suitable for cellular structures like breakwaters and artificial island seawalls. This article explores the design, mechanical properties, chemical composition, applications, and dimensional tolerances of straight web sheet piles, providing a comprehensive resource for engineers and contractors.

By integrating insights from industry leaders and standards, this article aims to highlight the unique advantages of straight web sheet piles, their role in modern construction, and their comparison with other piling solutions, including those specified in EN10219-1 and API 5L standards for pipe piling. Detailed tables summarize key parameters, ensuring a clear reference for practical applications.

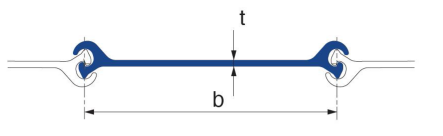

Straight Web Sheet Pile

| Section | Dimensions | Perimeter of single pile |

Sectional area |

Mass | Section modulus |

Moment of inertia |

||

| b | t | Per pile | Wall | |||||

| mm | mm | cm | cm2 | kg/m | kg/m2 | cm3 | cm4 | |

| GS 500 – 9.5 | 500 | 9.5 | 138 | 81.3 | 63.8 | 128 | 178 | 56 |

| GS 500 – 11.0 | 500 | 11.0 | 139 | 89.4 | 70.2 | 140 | 196 | 59 |

| GS 500 – 12.0 | 500 | 12.0 | 139 | 94.6 | 74.3 | 149 | 206 | 61 |

| GS 500 – 12.5 | 500 | 12.5 | 139 | 97.2 | 76.3 | 153 | 211 | 61 |

| GS 500 – 12.7 | 500 | 12.7 | 139 | 98.2 | 77.1 | 154 | 214 | 61 |

| GS 500 – 13.0 | 500 | 13.0 | 140 | 100.6 | 79.0 | 158 | 223 | 64 |

Design and Mechanical Properties

Straight web sheet piles are engineered to withstand horizontal tensile forces, primarily through the strength of their interlocks, rather than bending moments like Z-type or U-type sheet piles. The mechanical properties of these piles are defined by their ability to resist declutching under tension, with interlock strengths reaching up to 5,880 kN/m, as offered by Nippon Steel’s straight web sections. The steel grades typically used, such as S355GP or S430GP per EN 10248, provide a minimum yield strength of 355 N/mm² and 430 N/mm², respectively, ensuring robust performance in cellular structures. The tensile strength of these grades ranges from 490 to 600 N/mm², with elongation typically exceeding 20%, allowing for plastic deformation without failure.

The web of the sheet pile is designed with a uniform thickness, often incorporating a rolled-in taper to enhance plastic deformation capacity under dynamic loads, such as ship impacts or earthquakes. This feature, patented in designs like those described in US20070127991A1, ensures that the web deforms plastically before interlock failure, improving the pile’s resilience in cofferdams exposed to high stresses. The interlocks are critical, designed to resist horizontal forces corresponding to the web’s tensile load, with a nominal failure load typically less than 90% of the interlock’s guaranteed tensile strength. This allows for a plastic displacement distance of at least 1% of the pile’s width, enhancing energy absorption.

The stability of straight web sheet pile structures is guaranteed by the weight of the internal soil mass and the large diameter of the cells, which can reach significant heights and withstand substantial pressures. These properties make them ideal for deep-water applications and seismic regions, where traditional anchoring is challenging. The mechanical design ensures compliance with standards like EN 1993-5, which governs the resistance to interlock failure and web creep under tensile loads.

Chemical Composition

The chemical composition of straight web sheet piles is tailored to ensure high strength, weldability, and corrosion resistance, typically adhering to standards like EN 10248 for hot-rolled sheet piles. Common steel grades, such as S355GP and S430GP, have a maximum carbon content of 0.27%, manganese up to 1.70%, phosphorus and sulfur capped at 0.05%, and silicon up to 0.55%. Trace elements like nitrogen are limited to 0.011% to prevent embrittlement, while the carbon equivalent value (CEV) is controlled, typically below 0.45%, to ensure weldability. These compositions provide a balance of strength and ductility, critical for withstanding the tensile forces in cellular structures.

Compared to pipe piling grades like those in EN10219-1 (e.g., S355JOH with 0.22% carbon, 1.60% manganese) or API 5L PSL1 (e.g., X52 with 0.26% carbon, 1.40% manganese), straight web sheet piles have similar carbon and manganese contents but often include higher silicon for enhanced strength. The low phosphorus and sulfur contents minimize inclusions, improving toughness during pile driving. Microalloying elements like niobium and vanadium are typically absent or limited to trace amounts, simplifying manufacturing while maintaining performance. The controlled CEV ensures that welding, often required for junction piles or repairs, can be performed without excessive risk of cracking.

The chemical composition also contributes to corrosion resistance, adequate for marine environments with protective coatings. While not as corrosion-resistant as alloys like Incoloy 901 (40–45% nickel), the steel’s composition, combined with galvanizing or epoxy coatings, ensures durability in soil or water exposure. This makes straight web sheet piles a cost-effective solution for both temporary and permanent structures, such as cofferdams and quay walls.

Applications of Straight Web Sheet Piles

Straight web sheet piles are widely used in civil engineering projects requiring robust earth retention or water exclusion, particularly in conditions where traditional anchoring is impractical. Their primary application is in circular cofferdams, used for marine construction projects like bridge foundations, port developments, and offshore wind turbine installations. These temporary structures create a dry working environment by forming a watertight barrier, allowing excavation and foundation work in waterlogged conditions. The piles’ high interlock strength and large cell diameters ensure stability against water pressure and soil loads, making them ideal for deep-water applications.

Permanent structures, such as quay walls, breakwaters, and artificial island seawalls, also utilize straight web sheet piles due to their durability and load-bearing capacity. For example, ArcelorMittal’s AS 500 series is used in cellular structures for high retaining works and long structures, acting as self-supporting gravity walls without supplementary anchoring. Diaphragm cell configurations are employed in projects with specific site constraints, such as sloped bedrock, where circular cells may be less feasible. The piles are also used in seismic regions, where their ability to absorb dynamic stresses, such as those from earthquakes or ship impacts, enhances safety.

Other applications include temporary earth-retaining walls and foundation systems in shallow rock layers or high excavation depths. The versatility of straight web sheet piles, with interlock swings up to 12.5 degrees and lengths up to 38 meters, allows for customized configurations to meet project requirements. Their ease of installation, using vibratory or impact hammers, and adaptability to various soil conditions make them a preferred choice for both contractors and designers.

Dimensional Tolerances

Dimensional tolerances for straight web sheet piles are critical to ensure proper interlock engagement, structural integrity, and ease of installation, typically governed by EN 10248 standards. The outside width tolerance is ±2% of the nominal width, with a maximum of ±10 mm, ensuring consistent cell geometry. Wall thickness tolerances are ±1 mm for thicknesses up to 8 mm and ±1.5 mm for thicker sections, maintaining uniform strength. Straightness is limited to 0.2% of the pile length, preventing excessive deviation during driving. Interlock tolerances are tightly controlled to ensure watertightness, with a maximum deviation angle of 4.5 degrees per interlock, extendable to 12 degrees with special bending.

Compared to pipe piling tolerances (e.g., EN10219-2 with ±1% diameter tolerance, ±10% wall thickness), straight web sheet piles have stricter width and interlock tolerances due to their reliance on tensile interlock strength. Weld bead height is limited to 3.5 mm for thicknesses ≤13 mm and 4.8 mm for thicker sections, similar to API 5L standards, ensuring smooth surfaces for welding or coating. Mass tolerances are typically ±5%, ensuring consistency in large-scale projects. For junction piles, welded according to EN 12063, geometric tolerances are verified to maintain structural integrity.

These tolerances ensure that straight web sheet piles can be driven accurately, forming stable cellular structures with minimal leakage. Manufacturers like ArcelorMittal and Shunli Steel adhere to these standards, providing piles with precise dimensions for applications like cofferdams and breakwaters, where reliability is paramount.

Mechanical Properties Table

The following table summarizes the mechanical properties of common steel grades used for straight web sheet piles, based on EN 10248 standards, providing a reference for engineers and designers.

| Steel Grade | Min Yield Strength ReH N/mm² | Min Ultimate Tensile Strength Rm N/mm² | Min Elongation % | Interlock Strength kN/m |

|---|---|---|---|---|

| S355GP | 355 | 490–600 | 20 | Up to 5,500 |

| S430GP | 430 | 510–630 | 19 | Up to 5,880 |

This table highlights the high tensile strength and interlock capacity of straight web sheet piles, critical for their performance in cellular structures. Note that interlock strength varies by manufacturer and design, with values up to 5,880 kN/m achievable in premium sections like those from Nippon Steel.

Chemical Composition Table

The chemical composition of straight web sheet piles is summarized below, based on EN 10248 standards, ensuring weldability and corrosion resistance.

| Steel Grade | C Max % | Mn Max % | P Max % | S Max % | Si Max % | N Max % | CEV Max % |

|---|---|---|---|---|---|---|---|

| S355GP | 0.27 | 1.70 | 0.05 | 0.05 | 0.55 | 0.011 | 0.45 |

| S430GP | 0.27 | 1.70 | 0.05 | 0.05 | 0.55 | 0.011 | 0.45 |

This table provides a clear comparison of chemical compositions, aiding in the selection of grades for specific environmental and structural requirements.

Dimensional Tolerances Table

The dimensional tolerances for straight web sheet piles, per EN 10248, are summarized below, ensuring precision in manufacturing and installation.

| Parameter | Tolerance |

|---|---|

| Outside Width | ±2% Max ±10 mm |

| Wall Thickness | ≤8 mm: ±1 mm >8 mm: ±1.5 mm |

| Straightness | 0.2% of total length |

| Interlock Deviation Angle | 4.5° (up to 12° with bending) |

| Mass | ±5% |

| Weld Bead Height | ≤13 mm: 3.5 mm >13 mm: 4.8 mm |

These tolerances ensure reliable performance in cellular structures, minimizing issues during pile driving and interlock engagement.

Comparison with Pipe Piling and Z-Type Sheet Piles

Straight web sheet piles differ significantly from pipe piling (e.g., EN10219-1 and API 5L grades) and Z-type sheet piles in design and application. Pipe piling, such as S355JOH (yield strength 355 N/mm²) or API 5L X52 (yield strength 360 N/mm²), relies on compressive and shear strength for deep foundation support, with circular or tubular shapes providing high buckling resistance. Straight web sheet piles, with yield strengths like S355GP (355 N/mm²), focus on tensile interlock strength for retaining soil or water in cellular structures, offering flexibility in forming large-diameter cells but lower bending resistance compared to Z-type piles.

Z-type sheet piles, commonly used for retaining walls, rely on bending strength and stiffness, with interlocks designed for shear resistance rather than tension. They are unsuitable for filled cells, as their interlocks may stretch or flatten under tensile loads, unlike straight web piles, which excel in such conditions. For example, Z-piles lack the high interlock strength (up to 5,880 kN/m) of straight web piles, making them less effective for cofferdams or breakwaters. However, Z-piles are more versatile for linear retaining walls, where bending moments dominate.

Compared to Incoloy 901 (yield strength 900 N/mm², used in high-temperature applications), straight web sheet piles are more cost-effective for general construction, offering adequate corrosion resistance with coatings. The choice between these solutions depends on project requirements, with straight web piles preferred for cellular structures in marine or deep excavation settings.

Challenges and Considerations

The use of straight web sheet piles presents several challenges that require careful planning. Installation is complex, particularly for diaphragm cells on water, requiring precise templates and driving techniques to ensure interlock alignment. Vibratory or impact hammers are used, but soil obstructions can cause deviations, necessitating guide controls or panel driving techniques. Corrosion is a concern in marine environments, requiring coatings or cathodic protection, as the steel’s inherent resistance is lower than that of alloys like Incoloy 901. Thickness reduction due to corrosion must be factored into design life calculations.

Interlock strength is critical, and any failure can compromise the structure’s watertightness. Manufacturers like ArcelorMittal ensure robust interlocks, but dynamic loads (e.g., ship impacts, earthquakes) demand careful design, with tapers in the web enhancing deformation capacity. Soil conditions, such as cohesive soils with low bearing capacity, may require improvement with suitable backfill. Earthquake effects, including pore water pressure in cohesive soils, must be analyzed to ensure stability. The high cost of straight web piles, compared to Z-type or pipe piling, is a consideration, but their ability to form self-supporting gravity walls often justifies the expense in challenging conditions.

These challenges are mitigated through thorough site assessments, proper pile selection, and adherence to standards like EN 1993-5 and EN 12063, ensuring reliable performance in demanding applications.

Future Trends and Innovations

The future of straight web sheet piles is driven by advancements in materials, manufacturing, and sustainable construction practices. Innovations in steel production, such as thermomechanical rolling, are improving yield strength and interlock durability, allowing for thinner, lighter piles with reduced material costs. Additive manufacturing is emerging for custom junction piles, enabling complex geometries for unique project requirements. Research into high-strength, corrosion-resistant coatings is extending service life, reducing maintenance in marine environments.

The growing demand for offshore renewable energy, such as wind farms, is increasing the use of straight web sheet piles in large-diameter cofferdams and breakwaters. Digital tools, like real-time monitoring of pile driving and structural performance, are enhancing installation accuracy and safety. Sustainability is a key focus, with manufacturers like Shunli Steel exploring recycled steel and low-carbon production methods to align with environmental goals. These trends ensure that straight web sheet piles remain a vital solution for marine and deep excavation projects.

Collaborations between industry leaders like ArcelorMittal and research institutions are driving the development of next-generation sheet piles, with enhanced interlock designs and dynamic load resistance. As infrastructure projects expand globally, straight web sheet piles will continue to play a critical role, offering innovative, reliable solutions for the challenges of modern construction.

Straight web sheet piles are a cornerstone of civil engineering, offering a unique solution for retaining soil and water in challenging conditions through their high interlock strength and cellular design. With mechanical properties like yield strengths up to 430 N/mm² and interlock strengths exceeding 5,500 kN/m, they excel in applications like cofferdams, quay walls, and breakwaters. Their chemical composition ensures weldability and corrosion resistance, while strict dimensional tolerances per EN 10248 guarantee precision in installation. Compared to pipe piling and Z-type sheet piles, straight web piles are specialized for tensile loads in cellular structures, providing stability without anchoring.

Challenges such as corrosion, complex installation, and cost are mitigated through advanced coatings, precise driving techniques, and robust design standards. Future innovations in materials, manufacturing, and sustainability will enhance their performance, ensuring relevance in marine and infrastructure projects. The detailed tables provided in this article serve as a valuable reference for selecting straight web sheet piles, guiding engineers in optimizing safety and efficiency. By leveraging their unique properties, straight web sheet piles will continue to support the construction of resilient, sustainable structures worldwide.