Spiral weld pipe pile, otherwise known as SSAW Pipe pile, is a type of pipe piling product used in the construction of deep foundations. It is made from steel that has been formed into a spiral shape and welded together. It is used in a variety of applications, including bridge foundations, retaining walls, deep foundations for buildings, dams, and other large structures.

Spiral weld pipe pile is a high-strength, low-alloy steel pipe made from a combination of rolled steel plates and helically wound steel strips. It is highly resistant to corrosion and has a high strength-to-weight ratio, making it an ideal choice for deep foundations and other high-load applications.

The process of creating spiral weld pipe pile begins with hot-rolling a steel plate into a coil. This coil is then fed into a machine which shapes it into a spiral shape. This spiral is then cut into sections and welded together to form a single pipe pile. After the welding is complete, the pipe pile is then heat treated and tested to ensure it meets the desired specifications.

Spiral weld pipe pile is a strong and reliable choice for any deep foundation or other high-load application. It is resistant to corrosion and is lightweight, making it easy to transport and install. The welds are strong and consistent, and the pipe is designed to withstand high pressure and vibration.

Spiral weld pipe pile can be used in a variety of applications, including bridge foundations, retaining walls, deep foundations for buildings, dams, and other large structures. It can also be used to construct towers, poles, and other tall structures.

Spiral weld pipe pile is an environmentally friendly product as it is made from recycled steel. It is also a cost-effective solution for deep foundations, as it requires less material and labor than other types of pipe piles.

Spiral weld pipe pile is a reliable and durable product that can be used in a variety of applications. It is easy to transport and install, and is resistant to corrosion and vibration. It is an environmentally friendly product, as it is made from recycled steel. It is also a cost-effective solution for deep foundations, as it requires less material and labor than other types of pipe piles.

| Steel Pipe for Structure – steel pipe piles | GB/T 13793 | Longitudinally electric resistance welded steel pipe |

| SY/T 5040 | Spirally submerged arc welded steel pipe piles | |

| ASTM A252 | Welded and seamless steel pipe piles | |

| BS EN10219-1 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part1: Technical delivert conditions | |

| BS EN10219-2 | Cold formed welded structural hollow sections of non-alloy and fine grain steels – part2: tolerances dimmsions and sectional properties |

| PIPE WEIGHT (kg/m) | |||||||||||

| Outside Diameter (DO)(mm) | WALL THICKNESS (t) (mm) | ||||||||||

| 4.55 | 4.78 | 5.16 | 5.56 | 6.35 | 7.92 | 9.53 | 12.7 | 15.88 | 19.05 | 25.4 | |

| 219.1 | 24.05 | 25.23 | 27.2 | 29.29 | 33.31 | ||||||

| 254 | 27.97 | 29.35 | 31.64 | 34.08 | 38.78 | ||||||

| 273.1 | 30.1 | 31.59 | 34.06 | 36.69 | 41.76 | 51.81 | 60.3 | ||||

| 304.8 | 33.66 | 35.33 | 38.1 | 41.04 | 46.73 | 58.01 | 69.35 | ||||

| 323.9 | 35.8 | 37.57 | 40.52 | 43.66 | 49.71 | 61.74 | 73.83 | ||||

| 355.6 | 39.36 | 41.31 | 44.56 | 48.01 | 54.69 | 67.94 | 81.28 | 107.38 | |||

| 406.4 | 45.05 | 47.29 | 51.02 | 54.98 | 62.64 | 77.87 | 93.21 | 123.29 | |||

| 457.2 | 50.75 | 53.27 | 57.47 | 61.95 | 70.59 | 87.79 | 105.15 | 139.2 | |||

| 508 | 56.44 | 59.25 | 63.93 | 68.92 | 78.55 | 97.72 | 117.08 | 155.11 | 192.64 | ||

| 609.6 | 67.83 | 71.22 | 76.85 | 82.85 | 94.46 | 117.57 | 140.94 | 186.92 | 232.41 | 277.4 | |

| 762 | 118.32 | 147.36 | 176.73 | 234.65 | 292.07 | 348.99 | 461.35 | ||||

| 914.4 | 142.18 | 177.14 | 212.53 | 282.38 | 351.73 | 420.58 | 556.8 | ||||

| 1067 | 116.05 | 206.92 | 248.32 | 330.1 | 411.38 | 492.17 | 652.25 | ||||

| 1219 | 189.91 | 236.7 | 284.12 | 377.83 | 471.04 | 563.76 | 747.7 | ||||

| 1372 | 319.91 | 425.55 | 530.7 | 635.35 | 843.15 | ||||||

| 1524 | 355.7 | 473.28 | 590.35 | 706.93 | 938.6 | ||||||

| 1829 | 427.29 | 568.73 | 709.67 | 850.11 | 1129.5 | ||||||

| 2134 | 498.88 | 664.18 | 828.98 | 993.29 | 1320.41 | ||||||

| 2438 | 759.63 | 948.3 | 1136.46 | 1511.31 | |||||||

| 2743 | 855.08 | 1067.61 | 1279.64 | 1702.21 | |||||||

| 3048 | 950.53 | 1186.92 | 1422.82 | 1893.11 | |||||||

Please inquire about other diameters and thicknesses.

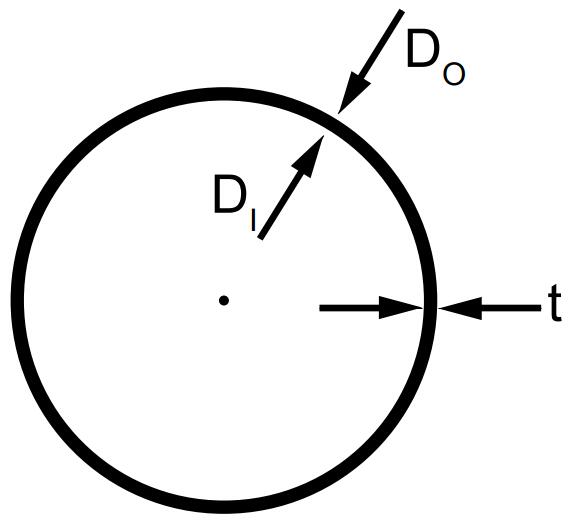

Pipe Weight (kg/m) = 0.0247*t*(d-t)

d (mm) – outside diameter

t (mm) – thickness of pipe

Tensile Strength of ASTM A252 Grade1,2, 3 Pipe

| ASTM A252 Grade 1 | ASTM A252 Grade 2 | ASTM A252 Grade 3 | |

|---|---|---|---|

| Tensile Strength | 50000(345) | 60000(415) | 66000(455) |

| Yield point or Yield Strength | 30000(205) | 35000(240) | 45000(310) |

| Elongation | 18 | 14 | – |

| Elongation | 30 | 25 | 20 |

difference between LSAW pipe piling and SSAW pipe piling ?

LSAW pipe piling and SSAW pipe piling are two types of pipe used in the construction of pipelines. Both are used to transport fluids or gases, and both are widely used in the construction of pipelines for oil, water, and other fluids.

LSAW (Longitudinal Submerged Arc Welding) pipe piling is a type of pipe that is welded using a submerged arc welding process. The pipe is welded in a helical pattern, which increases the strength of the pipe by evenly distributing the welded seam. LSAW pipe is generally used in applications where the pipe needs to be able to withstand high pressures and heavy loads.

SSAW (Spiral Submerged Arc Welding) pipe piling is a type of pipe that is welded in a helical pattern, much like the pattern used when welding LSAW pipe. The process is slightly different, however, as the welding is done in a spiral pattern, which helps to improve the strength of the pipe. This type of pipe is generally used in applications where the weld needs to be stronger than that of an LSAW pipe, as the weld is more evenly distributed.

When selecting a type of pipe for a project, there are a few factors to consider. First, the type of welding process used to create the pipe should be considered. LSAW pipe is welded using a submerged arc welding process, while SSAW pipe is welded using a spiral pattern. Depending on the project, one type of welding may be better suited than the other.

The thickness of the pipe should also be considered when selecting a type of pipe. Generally, LSAW pipe can be manufactured with thicknesses up to 100 mm, while SSAW pipe can be manufactured with thicknesses up to 120 mm. Depending on the specific project, one type of pipe may be better suited than the other.

The diameter of the pipe should also be taken into consideration when selecting a type of pipe. LSAW pipe is generally available in diameters up to 159 mm, while SSAW pipe is generally available in diameters up to 2032 mm. Depending on the specific project, one type of pipe may be better suited than the other.

The type of material used to create the pipe should also be taken into consideration when selecting a type of pipe. LSAW pipe is generally available in steel, stainless steel, and aluminum, while SSAW pipe is generally available in steel and stainless steel. Depending on the specific project, one type of pipe may be better suited than the other.

Finally, the cost of the pipe should also be taken into consideration when selecting a type of pipe. Generally, LSAW pipe is more expensive than SSAW pipe due to the increased complexity of the welding process. Depending on the specific project, one type of pipe may be more cost-effective than the other.

In conclusion, LSAW pipe piling and SSAW pipe piling are two different types of pipe used in the construction of pipelines. Both types of pipe are used to transport fluids or gases, but they are welded in different ways. LSAW pipe is welded using a submerged arc welding process, while SSAW pipe is welded using a spiral pattern. The thickness, diameter, material, and cost of the pipe should all be considered when selecting a type of pipe for a project.