water

The Perforated Casing Pipe and What You Need to Know

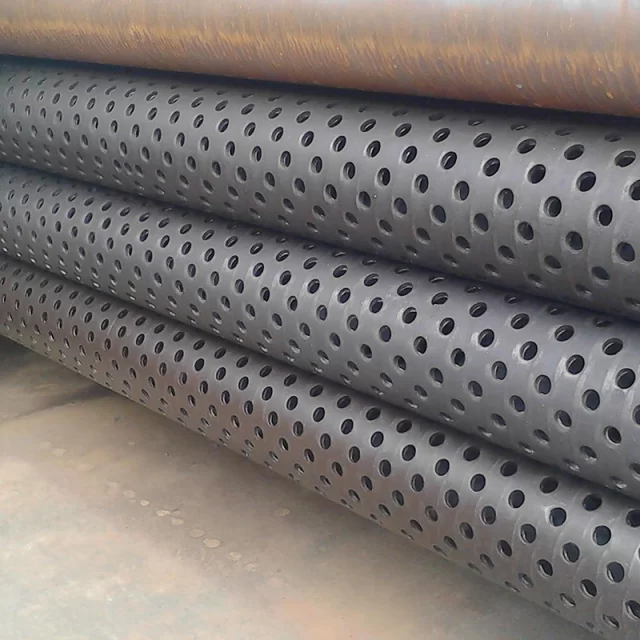

Perforated casing pipes are indispensable components in various industries, providing essential support and fluid flow capabilities in well construction. Understanding their design, applications, and manufacturing processes is crucial for selecting the right pipe for specific needs. By considering factors such as well conditions, flow requirements, and corrosion resistance, operators can optimize the performance and longevity of perforated casing pipes. As technology continues to advance, new materials and manufacturing techniques will further enhance the capabilities of these vital components, ensuring their continued relevance in the ever-evolving landscape of drilling and well construction.

High Precision Wedge Wire Screen Filter Pipe

With these detailed characteristics and specifications, high precision wedge wire screen filter pipes offer reliable and efficient solutions for a wide range of industrial filtration needs. Their customizable features and durable construction ensure optimal performance in even the most demanding environments.

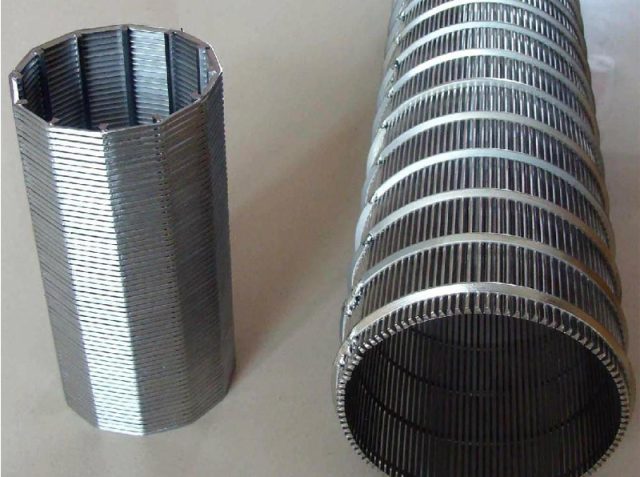

Johnson Wedge Wire Screen (V Wire Panel)

Johnson wedge wire screens (V wire panels) are a versatile and reliable solution for various industrial filtration applications. Their unique design, high efficiency, and durability make them suitable for use in water treatment, mining, food and beverage, pulp and paper, oil and gas, and architectural applications. Customizable slot sizes and dimensions ensure that these screens can meet specific filtration requirements, providing long-lasting and low-maintenance performance.

Galvanized Bridge Slot Screen Pipe

Galvanized Bridge Slot Screen Pipe is a reliable and efficient filtration solution that offers enhanced corrosion resistance and durability. With its bridge slots and galvanized coating, it provides optimal filtration performance while withstanding harsh environments. Whether it's for water wells, oil and gas operations, mining, or environmental protection, Galvanized Bridge Slot Screen Pipe is a valuable asset. Consider utilizing this specialized pipe for your filtration needs and experience its benefits in ensuring efficient and reliable filtration.

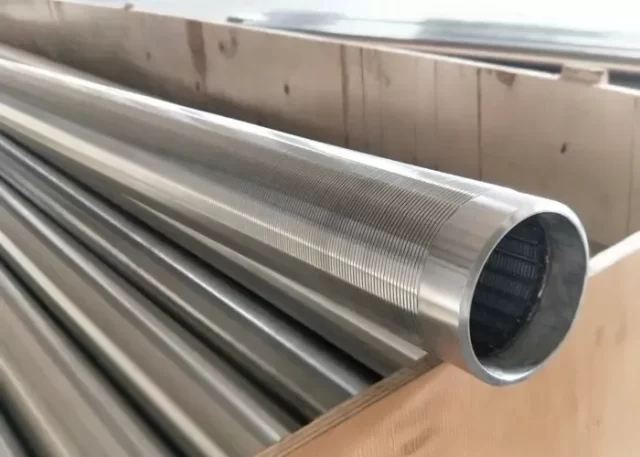

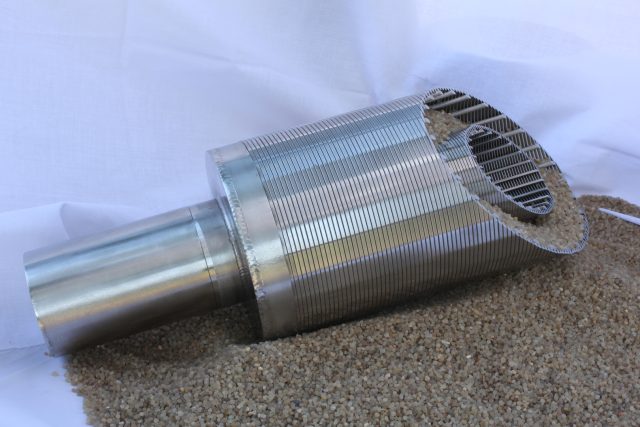

V Wire Wrap Well Screen Pipe: A Reliable Solution for Filtration

V Wire Wrap Well Screen Pipe offers a reliable and efficient solution for filtration needs. Its high-quality construction, precise slot design, and customizable options make it a versatile choice for various industries and applications. Whether it's for residential or industrial use, the V Wire Wrap Well Screen Pipe provides optimal flow rates, durability, and excellent filtration performance. Consider using V Wire Wrap Well Screen Pipe for your filtration needs and experience its benefits firsthand.

Sand Control Well Screen | Bridge Slotted Screen pipe

Bridge slotted screen pipes are a valuable tool in sand control for wells across different industries. Their ability to effectively prevent sand production, provide high flow rates, and maintain structural integrity makes them a preferred choice for many well operators. Whether it's an oil and gas well, a water well, or an environmental remediation project, bridge slotted screen pipes offer a versatile and reliable solution. Consult with a well professional to determine if bridge slotted screen pipes are suitable for your specific well needs and ensure the long-term productivity and efficiency of your well system.

When Should Replace well screen casing pipe ?

The wire wrapped screen from abterstee provides a reliable and effective method of preventing gravel-pack sand from entering the pipe, while allowing production fluids to flow into the well.The product acts as a sand-retaining device placed in the well. Compared to normal slotted tube, inflow area of the same opening sand screen mesh size is 30 times larger, which prolongs the well life.

Johnson Type Water Well Screens – Maximizing Water Well Performance with : Innovative Solutions for Reliable Water Supply

Johnson Type Water Well Screens offer various unit arrangements to accommodate different project needs. The protective shroud can be customized with perforations or louvers and is designed to accommodate a fiber-optic cable. The wire jacket is available in stainless steel or alloy/carbon steel material, and for special applications, a direct wrap option can be utilized, eliminating the need for welding to the base pipe. These features ensure the reliability and efficiency of Johnson Type Water Well Screens for a wide range of water well applications.

Johnson Stainless Steel Well Screens: Empowering Reliable and Efficient Water Wells

Advantages of Slot Wire Wrapped Water Well Screen Pipe

1. Better filter function

2. Prolong life of well

3. Long service life

4. High pressure-resistant

5. Customized Specifications

How to Clean a Stainless Steel Well Screen

Stainless Steel Water Well Screens and Accessories

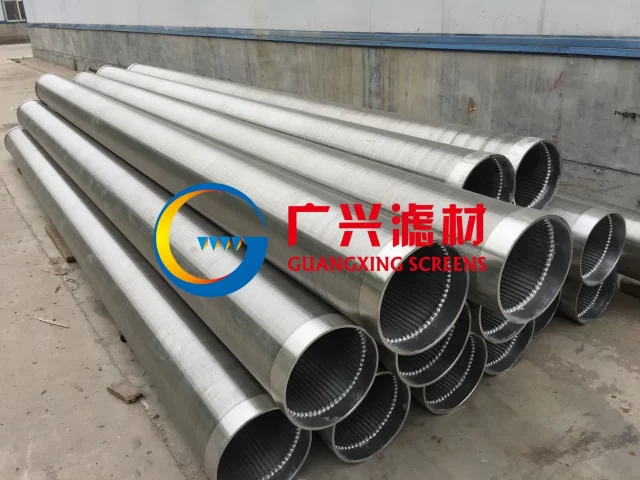

abter well Screens is one of the largest manufacturers of stainless steel water well screens in the world. With a high open

area, allowing for better access to the entire formation around the screen; fines and drilling fluid are removed quickly

and completely, resulting in a better well development.

Custom Slot Well Screen Pipe | Slotted Perforated Well Screen for Casing

Product Continuous slot well screen, wire screen, Johnson screen Slot Size(mm) 0.10, 0.15, 0.2, 0.25, 0.30-3, also achieved upon customer request. Material Low Carbon ,Low Carbon Galvanized steel (LCG), Stainless Steel( 304,etc.) Lengths up to 6 meters Diameter 89 mm to 1200 mm End Connection Plain beveled ends, welding rings, flanges or threaded ( Thread...

Perforated Casing Pipe | Perforated Well Screen Piping

Applications of Perforated Pipe: Perforated well screen is a type of filter used in oil and gas wells. It is designed to control the flow of oil and gas from the well, while preventing sand and other debris from entering the well. perforation in the context of oil wells refers to a hole punched in...

Slotted Casing Pipe | Slotted Liner Well Screen – API 5CT

1. Introduction of Slotted Casing Pipe Casing pipe is a large-diameter pipe that serves as the structural retainer for the walls of oil and gas wells, or well bore. It is inserted into a well bore and cemented in place to protect both subsurface formations and the wellbore from collapsing and to allow drilling...

Well Screen Oil Casing , Pipe Based ,Sand Control,API 5CT

1. Grade: SUS 304 SUS304L, SUS316, SUS316L, or carbon steel 2. Slot Size: 0.02mm~15mm 3. Standard: DIN AISI ASTM 4. Certification: ISO9001, API 5CT 5.Pipe based well screens consist of base pipe,all-welded wedge wire screen and supporting rod.The base pipe is perforated or slotted API casing pipe,the base pipe can be stainless steel or carbon...

Pre-packed well screen | Wire Wrapped Pre Packed Sand Screen

Pre Packed Sand Screen contains perforated base pipe, inner and outer screen jackets and graded sand between the jackets. It is a modification of wire wrapped screen which is used in well sorted sand or stand-alone completion. Graded sand, with or without resin coating, is considered as a filter for reservoir particles. Wire wrapped pre...

Geothermal Pipe Based Screen | Sand Free Pipe Based Well Screen

PARAMETER Geothermal Pipe based well screen specification: Nominal Diameter Pipe OD(mm) Weight lb/ftW.T[mm] Hole size In Holes per foot Total Areaofholes in2/ft Screen OD (in) 2-3/8 60 4.6[4.83] 3/8 96 10.60 2.86 2-7/8 73 6.4[5.51] 3/8 108 11.93 3.38 3-1/2 88.9 9.2[6.45] 1/2 108 21.21 4.06 4 101.6 9.5[5.74] 1/2 120 23.56 4.55 4-1/2 114.3...

Water well screen pipe | Sand Control Screen

The water well screen is an important component of a well that allows water to flow into the well while preventing sediment and other debris from entering. The screen is typically located at the bottom of the well, near the aquifer. This is done to ensure that only clean water is collected and that...