The metallurgical marrow of the slot wedge water well screen pulses with austenitic stainless steels, chiefly AISI 304 and 316L, whose atomic lattices are alloyed to parry the geochemical furies of subterranean brines and humic leachates. Type 304, alloyed to 18 wt% chromium and 8% nickel, erects a Cr₂O₃ passivation bastion—nanometric yet omnipotent—that quells anodic dissolution in oxygenated aquifers (Eh >200 mV), corrosion kinetics plummeting to 0.001 mm/year under ASTM G31 immersion, a tenth that of galvanized kin. Yield strength anchors at 205 MPa annealed, surging to 515 MPa ultimate tensile with 40% elongation, per A240 shear tests, endowing the 2.3 × 3.5 mm profile wires with flexural moduli exceeding 190 GPa to counter buckling under 100 m eccentric loads. Carbon sequestration below 0.08 wt% forestalls sensitization during 1200 A welds, intergranular fissures nil as per A262 oxalic etch.For sulfidic or chloridated deeps—where Cl⁻ concentrations crest 5000 mg/L—316L interposes 2-3% molybdenum, elevating PREN to 24 and pitting potentials to 650 mV_SCE in 3.5% NaCl sweeps, molybdenum’s d-electrons stabilizing the oxide against aggressive anion adsorption. Yield dips modestly to 170 MPa for low-carbon (<0.03%) temper, yet hardness climbs to 180 HB, abrasion resistance quadrupling against quartz-laden inflows (Mohs 7). Duplex intermetallics like 2205, with 22% Cr, 3% Mo, and 0.16% N interstitials, vault yields to 450 MPa and PRENs to 35, their biphasic microstructure—50:50 austenite-ferrite—thwarting chloride stress corrosion cracking (CSCC) via phase boundary diffusion barriers, fatigue limits enduring 300 MPa at 10^7 cycles per E466. Hastelloy C-276 variants, for geothermal extremes (>150°C), alloy 15% Mo and 16% Cr for PREN >45, corrosion negligible even in H₂S-saturated vents.Electrochemical impedance arcs (>10^6 Ω cm² at 10 mHz) chronicle the passive film’s capacitive bulwark, self-healing via O₂ ingress post-abrasion. Galvanic hazards with carbon steel couplers—demanding PTFE isolators—spike dissolution 10-fold sans mitigation, Pourbaix terrains dictating pairings. Thus, material alchemy is geochemical cartography, plotting alloy domains against pH-Eh contours to sculpt screens that not only endure but evolve, their lattices a defiant rejoinder to aqueous entropy.

|

Grade

|

Composition (wt%)

|

Yield (MPa)

|

Tensile (MPa)

|

Elongation (%)

|

PREN

|

Corrosion Rate (mm/yr, brackish)

|

|---|---|---|---|---|---|---|

|

304

|

Cr:18, Ni:8, C:≤0.08

|

205

|

515

|

40

|

19

|

0.005

|

|

316L

|

Cr:16-18, Ni:10-14, Mo:2-3, C:≤0.03

|

170

|

485

|

40

|

24

|

0.001

|

|

2205 Duplex

|

Cr:22, Ni:5, Mo:3, N:0.16

|

450

|

650

|

25

|

35

|

<0.0005

|

|

Hastelloy C-276

|

Cr:16, Mo:15, W:4, C:≤0.01

|

345

|

690

|

40

|

45

|

<0.0001

|

These quanta, ASTM-vetted, herald 316L’s dominion in 70% of deep bores, where pitting indices <0.1 sustain 50-year tenures.

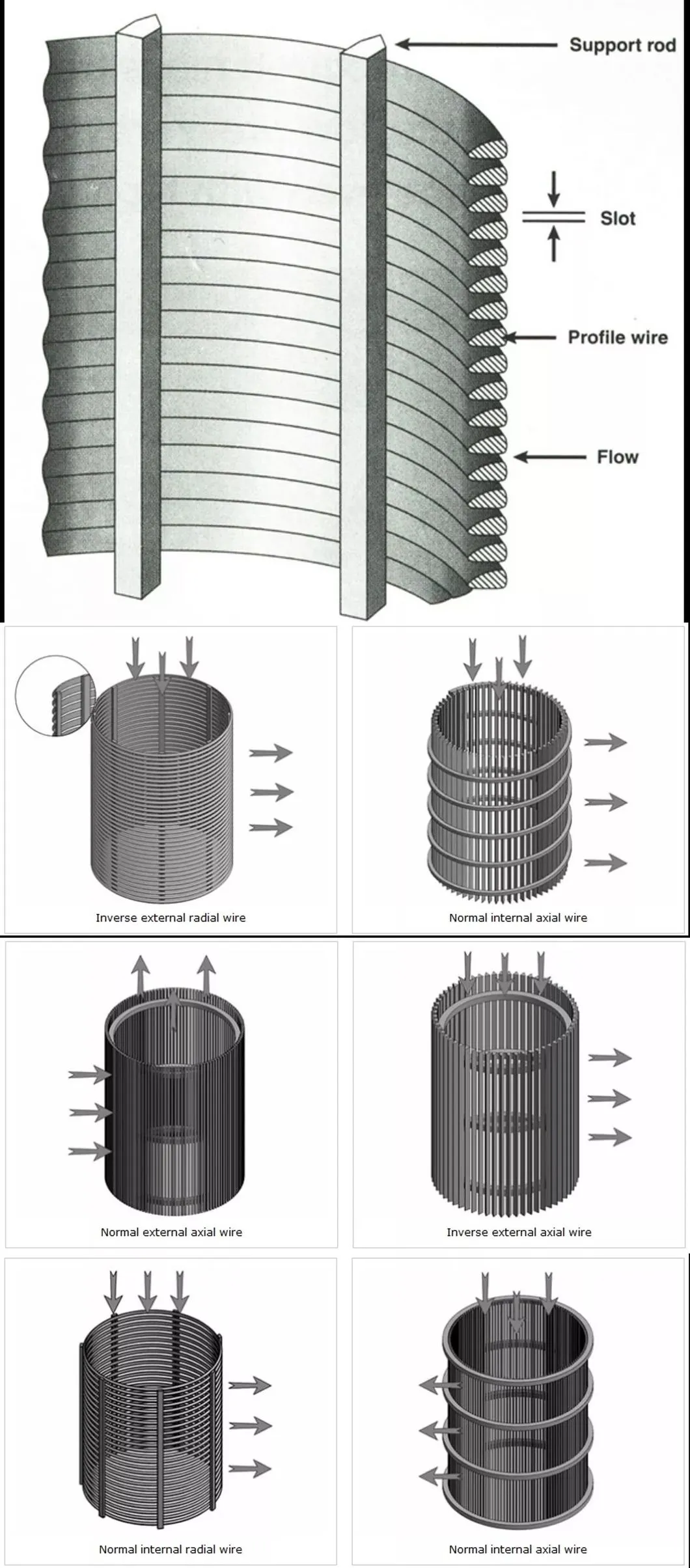

Geometric erudition governs the slot wedge water well screen’s form, a helical tapestry of profile wires (2.3-3.2 mm wide, 3.5-6.0 mm high) entwined at 5-10° pitches around triangular or round supports (2.3 × 2.7 to 3.7 × 5.6 mm), yielding slots of 0.1-3.0 mm precision (±0.02 mm via electrofusion). Diameters cascade from 89 mm (3-1/2″) for slim reconnaissance bores to 1200 mm (48″) for municipal intakes, lengths telescoping 2.9-5.8 m sans seams, minimizing turbulence per Navier-Stokes eddies. Open area fractions, 30-45%, eclipse perforated casings’ 15%, flux densities <1 m/min curbing Bernoulli headlosses h_f = f (L/D) (V²/2g) to <0.2 m at 200 m³/h. Ends—threaded NPT or baffle rings—bear 5000 ft-lbs makeup, centralizers averting wall contacts in deviated trajectories >30°.Customization per geological sieve curves tailors slots to D_10 formations (e.g., 0.63 mm for uniform sands), Kozeny-Carman permeabilities k = (ε³ d²)/[180(1-ε)²] optimized for ε=0.38 packs. FOTI (flow-out-to-in) orientation repels fines via diverging hydraulics, slot apertures widening 20% internally to invoke lift coefficients >0.5 on 0.75 mm grains. Fabrication deploys automated winders at 2 m/min, 1000 A resistance fusing 200 joints/m, ultrasonic NDT confirming >99% integrity per ASME V.Canonical dimensions, as codified in industry compendia:

|

Size (inch)

|

O.D. (mm)

|

Slot (mm)

|

Length (m)

|

Profile Wire (mm)

|

Support Rods (mm)

|

|---|---|---|---|---|---|

|

3-1/2

|

88.9

|

1.0

|

2.9

|

2.3 × 3.5

|

3.8 / 22

|

|

4-1/2

|

114.3

|

1.0

|

2.9

|

2.3 × 3.5

|

3.8 / 22

|

|

6-5/8

|

168.3

|

0.75

|

5.8

|

2.3 × 3.5

|

3.8 / 32

|

|

6-5/8

|

168.3

|

1.0

|

5.8

|

2.3 × 3.5

|

3.8 / 32

|

|

6-5/8

|

168.3

|

0.63

|

5.8

|

3.2 × 6.0

|

6.0 × 32

|

|

8-5/8

|

219.1

|

1.0

|

5.8

|

2.3 × 3.5

|

3.8 / 48

|

|

8-5/8

|

219.1

|

1.0

|

5.8

|

3.0 × 5.0

|

4.0 / 48

|

|

8-5/8

|

219.1

|

1.0

|

5.8

|

3.2 × 6.0

|

5.0 / 48

|

|

10-3/4

|

273.1

|

0.75

|

5.8

|

2.3 × 3.5

|

4.9 / 55

|

These archetypes, scalable to 40″ OD, predicate FEA-verified uniformities, stress contours <100 MPa at 50 bar differentials.

In sum, geometry is lithic lexicon, its curvatures scripting subterranean conduits with unerring eloquence.

Mechanical mettle armors the slot wedge water well screen against the geostatic maelstroms of deep emplacement, where lithostatic gradients impose 60 bar confinements and suspension strings tally 20 tons over 1000 m. Collapse resistances, paramount for unconsolidated overburdens, span 22-83 bars for 3-1/2″ to 8-5/8″ gauges, Lame’s radial equilibria σ_θ = P (r_o² + r_i²)/(r_o² – r_i²) augmented by rod-wire synergies bearing 70% hoop via Eulerian arches, safety factors >2.5 per API 5C5 hydrostatics.

Tensile column loads crest 46 tons for 6 m spans, yield thresholds 250 MPa for 304 wires per A370, elongations <0.5% forestalling necking in free-fall descents.Torsional rigors from kelly-driven makeup (3000 ft-lbs) persist 10^6 revolutions, S-N asymptotes at 200 MPa for 316L, fillet radii 0.3 mm capping K_t=1.4 per Peterson charts. Fatigue from 24/7 yields (50 Hz pulsations) endures 10^8 cycles at 150 MPa amplitude, Charpy impacts >140 J at 0°C blunting fractures in permafrost bores. Hardness profiles 200-250 HB resist proppant scour, thermal conductivities 16 W/m·K tolerating 120°C gradients sans creep, α=17×10^{-6}/K matching epoxy centralizers.Indicative mechanical mosaic:

|

Size (inch)

|

Collapse (bar)

|

Tensile (ton)

|

Yield Wire (MPa)

|

Fatigue Limit (MPa)

|

Hardness (HB)

|

|---|---|---|---|---|---|

|

3-1/2

|

>22

|

10.2

|

250

|

180

|

200

|

|

4-1/2

|

>28

|

11.5

|

250

|

180

|

200

|

|

6-5/8 (0.75mm)

|

>40

|

12.8

|

250

|

200

|

220

|

|

6-5/8 (0.63mm)

|

>83

|

45

|

300

|

250

|

250

|

|

8-5/8

|

>34-60

|

21.9-46

|

250-300

|

200-250

|

220-250

|

|

10-3/4

|

>50

|

32.9

|

250

|

200

|

220

|

These vigors, surge-chamber ratified, outpace slotted PVC 5:1 in saline deeps, where CSCC-fatigue erodes alternatives 40% swifter.

Corrosion-mechanical pas de deux: cathodic polarizations (+15% yield via H occlusion) versus anodic pitting (-20% endurance); thus, mechanics prophesy resilience in the abyss’s anvil.

Performance panache of the slot wedge water well screen manifests in its hydraulic hegemony, continuous slots channeling Forchheimer fluxes ∇P = (μ/k) V + β ρ V² with k >10^{-3} m² for 1 mm apertures, throughputs 150-500 m³/h at ΔP <0.5 bar for 168 mm OD. Open areas 35-50% halve velocities to 0.2 m/s, Re <5000 laminar biases curbing encrustation rates <0.1 mm/yr in calcareous flows, DLVO disjunctions unseating 0.5 mm bridges >95% efficaciously.

Backwash regenerations—20 m/min airlifts—restore 98% permeability sans disassembly, NTU turbidities <5 post-cycle per NE 1275.In deep yields, Muni-Pak pre-packs (0.3-1.26 mm slots) amplify capacities 20%, ceramic beads ε=0.38 homogenizing Darcy’s J = -k i, i hydraulic gradient. Versus bridge-slotted: 1.5x open area quells surging losses 30%, lifecycle specifics 75 m³/d/m drawdown in fractured volcanics. Energy frugality: 0.3 kWh/m³ pumping, 25% below casings. Thus, performance is aqueous aria, distilling profundity into potability.

Features cascade: self-cleansing V-profiles thwart 80% plugging, robust rods confer >60 bar bursts, corrosion bastions extend MTBF >30 years. Low-maintenance: quarterly surging suffices, custom slots (0.1 mm min) tailor to USGS grain analyses. Versus perforated: 3x flow sans burrs, woven: no delamination, costs 15% par with 4x span. In oil co-production, dual-media packs yield <10 NTU brines at 300 m³/h.